The dream of building boat docks is a cornerstone of the waterfront lifestyle, transforming a simple shoreline into a functional and beautiful hub for recreation and relaxation. This endeavor is more than just a construction project; it’s an investment in your property and your passion for the water. To succeed, you need a solid understanding of dock design, a clear path through the permitting process, a wise choice of materials, and a commitment to long-term maintenance. This guide will walk you through every stage, ensuring the dock you build is not only stunning but also safe, durable, and perfectly suited to your needs. For those starting at the very beginning, exploring a wide range of boat dock ideas is the perfect first step to spark your imagination.

Before You Hammer the First Nail: Planning Your Dock Build

Jumping into construction without a thorough plan is a recipe for disaster. The planning phase is where your project’s success is truly decided. It involves assessing your unique environment, navigating local regulations, and making fundamental design choices that will affect your dock’s function for years to come. Rushing this stage often leads to costly mistakes and a structure that doesn’t meet your expectations.

Understanding Your Waterfront

Every shoreline has its own personality, and your dock design must respect it. Begin by evaluating the water body itself. Is it a calm lake, a river with a current, or a coastal area with tidal fluctuations? The water depth, both at the shore and further out, will dictate the length and type of dock you can build. The lakebed or seafloor composition—be it soft mud, sand, or rock—is a critical factor in determining the right kind of foundation or anchoring system. Furthermore, understanding the context of your water body is key; for instance, recognizing the differences in shoreline stability between a natural spring-fed lake and learning how are man made lakes made can influence your structural choices.

What Permits Do I Need for Building a Boat Dock?

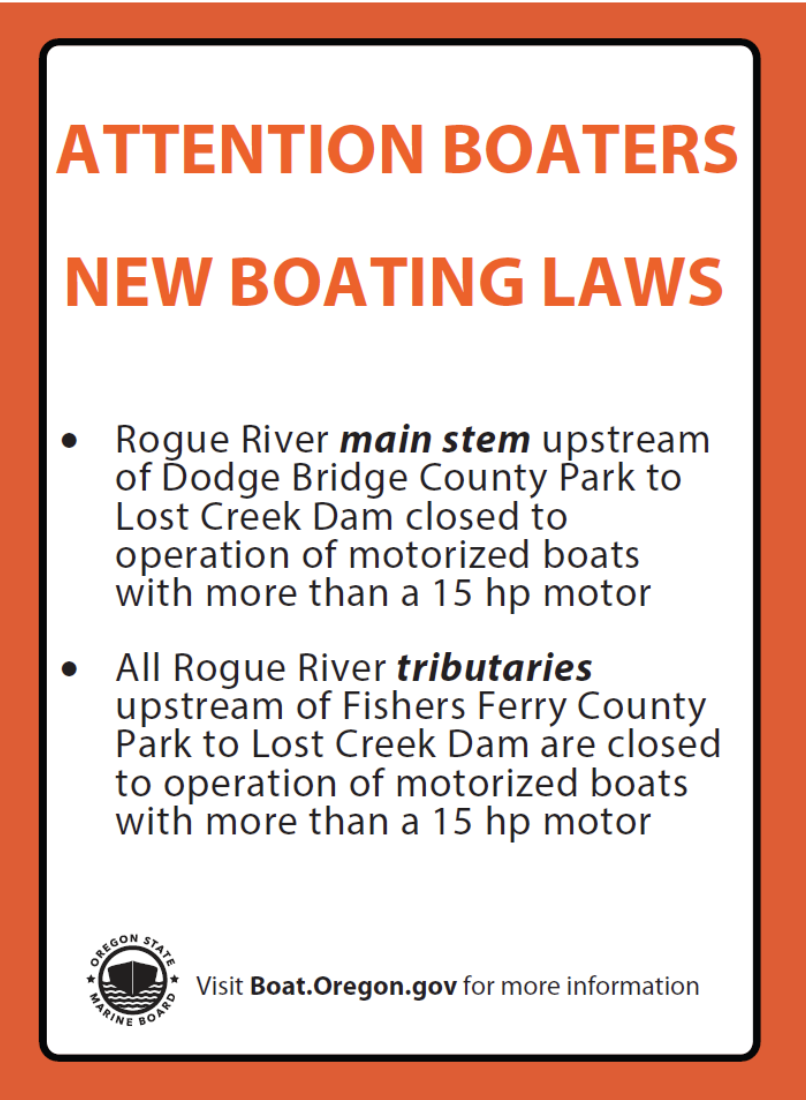

This is often the most daunting question for aspiring dock builders. The answer is almost always: yes, you need permits. Navigating the bureaucracy is a non-negotiable step. Your journey will typically start with your local municipal or county planning office. They will provide a checklist of requirements, which may include environmental impact assessments, detailed structural plans, and proof of property lines. In many regions, you may also need approval from state or federal agencies, such as the Army Corps of Engineers in the U.S., especially if your waterfront is considered navigable waters. Don’t view this as a hurdle, but as a safeguard that ensures your project is safe, environmentally sound, and legally compliant.

As marine construction consultant David H. Sterling often advises, “Skipping the permitting process is the most expensive shortcut you can take. It’s far cheaper to get the paperwork right the first time than to pay fines or, worse, be forced to tear down a completed dock.”

Choosing the Right Dock Style: Fixed vs. Floating

Your primary design decision is whether to build a fixed or a floating dock. A fixed dock, also known as a stationary or pile dock, is built on pilings driven deep into the seabed. It offers unmatched stability, making it ideal for areas with heavy boat traffic and for supporting structures like boathouses. However, its height is constant, which can be inconvenient in areas with significant water level fluctuations.

A floating dock, on the other hand, consists of a deck built on airtight pontoons that allow it to rise and fall with the water level. This makes it incredibly versatile for tidal areas or reservoirs. While easier to install and often more budget-friendly, it can be less stable in rough water compared to its fixed counterpart.

| Feature | Fixed Dock | Floating Dock |

|---|---|---|

| Best For | Stable water levels, heavy use, boathouses | Fluctuating water levels, tidal areas, easy installation |

| Stability | Extremely high | Moderate to high, can be affected by waves |

| Maintenance | Requires piling inspection | Requires inspection of floats and connectors |

| Cost | Generally higher initial cost | Often more affordable upfront |

The Heart of the Matter: Selecting Dock Materials

The materials you choose will define your dock’s appearance, durability, and maintenance schedule. The decision goes beyond just the walking surface; it includes the structural frame and the hardware that holds everything together. A well-built dock is a system where every component works in harmony.

The Classic Choice: Wood Decking

Wood is the traditional and often most aesthetically pleasing option. Pressure-treated pine is the most common and affordable choice, offering good resistance to rot and insects. For a more premium look and enhanced natural durability, hardwoods like cedar or redwood are excellent, though they come at a higher price. The timeless appeal of a wooden structure is undeniable. To explore the nuances of different wood types and construction methods, diving into the world of wooden docks can provide valuable insight and inspiration for your project.

Modern Marvels: Composite and Plastic Decking

For those who prioritize low maintenance over traditional aesthetics, composite and PVC (plastic) decking are fantastic alternatives. Composite decking is made from a blend of wood fibers and recycled plastic, offering the look of wood without the risk of splintering, rotting, or insect damage. It never needs staining or sealing. Pure plastic or PVC decking offers similar benefits and is often lighter and completely impervious to moisture, making it a superb choice for a long-lasting, worry-free surface.

The Unseen Hero: Framing and Hardware

The strength of your dock lies in its frame and the hardware that connects it. The frame is typically constructed from pressure-treated lumber or, for superior strength and longevity, galvanized steel or aluminum. All hardware—including bolts, screws, and connectors—must be hot-dip galvanized or stainless steel. Using the wrong hardware is a common failure point, as standard steel will corrode quickly in a marine environment. Components like a sturdy 2 pipe bracket are essential for securing the frame to the pilings, and compromising on their quality is never a good idea.

A Step-by-Step Approach to Building Boat Docks

With your plans approved and materials on site, the construction phase begins. This process should be methodical and precise. The first and most critical step is establishing the foundation. For a fixed dock, this means professionally driving pilings into the lakebed or seabed to the required depth to ensure they are secure against uplift from ice or wave action. For a floating dock, it involves assembling the float sections and creating a secure anchoring system.

Once the foundation is set, the structural frame is built on top of the pilings or attached to the float sections. This grid-like structure is what will support the decking. It is paramount that all joists are level, square, and securely fastened according to your engineered plans. This framework is the skeleton of your dock, and its integrity determines the overall strength of the finished product.

With the frame complete, you can begin installing the decking. Start from one end and work your way across, ensuring you leave a consistent, small gap between boards to allow for drainage and expansion. Use high-quality, corrosion-resistant screws to fasten the boards to the joists. Finally, add the finishing touches. This includes installing cleats for mooring boats, bumpers to protect hulls, and perhaps a ladder for swimmers. Optional accessories like built-in benches, lighting, or a fish-cleaning station can truly personalize your dock.

Beyond the Build: Dock Maintenance and Safety

Your responsibility doesn’t end when the last screw is tightened. Regular maintenance is key to ensuring your dock remains safe and lasts for decades. At least twice a year, in the spring and fall, conduct a thorough inspection. Check all hardware for tightness and signs of corrosion. Examine the decking for loose or damaged boards. For fixed docks, inspect the pilings for any signs of decay or shifting. For floating docks, check the floats for leaks and ensure all connections are secure.

David H. Sterling emphasizes, “A dock is a dynamic structure in a harsh environment. Treat it like your boat—it needs regular attention. Staying ahead of small repairs prevents them from becoming major, costly problems.”

Keeping up with the latest in dock technology and materials can also extend the life of your investment. Attending events like a docks expo can expose you to new products for maintenance, innovative accessories, and improved building techniques that you can incorporate over time.

Properly building boat docks is a rewarding project that adds immense value and enjoyment to any waterfront property. From the initial spark of an idea through meticulous planning, careful material selection, and precise construction, the journey results in more than just a structure. It creates a personal gateway to the water, a place for making memories that will last a lifetime. By following these guidelines and respecting the power of the environment, you can build a dock that stands strong for generations.

Comments

Mark T.

★★★★★

This guide was exactly what I needed. I’m a fairly handy DIYer but was intimidated by the permitting process. The advice to treat it as a safeguard rather than a hurdle really changed my perspective. We just got our plans approved and are ordering materials next week. Thanks for breaking it down so clearly!

Sarah and Tom Jennings

★★★★★

Fantastic article! We just finished building our floating dock on the lake last month, and this guide mirrors so many of the lessons we learned along the way. The section on choosing materials is spot on—we went with composite and are so happy we did. It looks amazing and the idea of no staining is a huge plus.

Brian P.

★★★★☆

Great information here. Very comprehensive. One question: for a fixed dock in an area that gets heavy ice in the winter, what’s the best way to protect the pilings from ice heave? Is a bubbler system the only option? Would love a follow-up on winterization techniques.

Eleanor Vance

★★★★★

As someone who has lived on the water for 40 years, I can attest to the wisdom in this post. The emphasis on high-quality, hot-dip galvanized hardware cannot be overstated. I’ve seen too many neighbors’ docks fail because they tried to save a few bucks on bolts and brackets. Pay for the good stuff; it’s worth every penny.

Miguel R.

★★★★★

This was incredibly helpful, even for us here on the Gulf Coast where we deal with tides and hurricanes instead of ice. The breakdown of fixed vs. floating docks was perfect for explaining the options to my wife. We’re leaning towards a floating system connected to a fixed pier. Thanks for the solid advice.